Plasma reactor D-CRBN makes new raw materials out of CO2

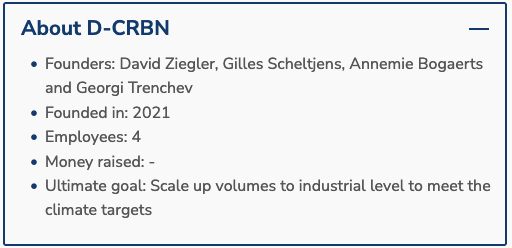

Every day Innovation Origins puts a start-up in the spotlight. Today, it is the Antwerp-based D-CRBN

The start-up D-CRBN wants to build plasma reactors in the Belgian port of Antwerp to convert CO₂ captured from industry into carbon monoxide. This is how they want to make new fuels, chemicals and chemical raw materials. This should have a positive impact on the climate. David Ziegler, one of the founders of the company, talks more about it in this instalment of Start-up of the day. The project is the result of 10 years of research at the University of Antwerp. It concerns an investment of several million euros.

You transform CO₂ into a product with the help of a plasma reactor. How does this work?

“Using our plasma reactor, we generate lightning that breaks down the CO₂ into carbon monoxide. This is used to make a lot of chemical products. We are the successor to the CCS story, which stands for carbon capture and storage. We are actually putting the CO₂ to use. This is called carbon capture and utilization (CCU). This is where we make a big difference compared to other technologies.”

What is the timeline for this?

“We hope to build our first test line around the summer period. All of this is taking place on the Blue Gate site. Our production hall is ready. This has never been done before. We aspire to have the first industrial plant up and running within three years. A plant that can break down 30-50,000 tonnes of CO2 per year. And within five years, we hope to have industrial recycling plants, each capable of processing 1 million tonnes per year. To offset 1 million tonnes of CO2, you have to plant 45 million trees.”

The plasma reactors can be switched on and off with a simple push of a button. So when a surplus of renewable energy is available, they can be switched on. What impact will the prototype have?

“These are still just prototypes. At the moment, their impact is still quite small. You can’t scale up from a lab environment to an industrial application straight away. That takes time. Once we have scaled it up to a commercial unit, it will become industrially relevant. In the future, we intend to place mobile units at strategic locations where you can convert between 30,000 and 50,000 tonnes of CO₂ per year. You can place these mobile units anywhere at a clients’ premises. That is something that will be listened to.”

The prototype is just the beginning. You have bigger plans. So what do they entail?

“We would like to make our big dream come true by 2030. It’s a recycling plant, a kind of factory that gets CO₂ from a variety of clients. We can then cater to other customers as well. Everything can be transported to us through one pipeline, where we then break down the CO₂ on site. To do this, we have aspirations to have a site on the Antwerp NextGen District, located in the Port of Antwerp. That is our dream. Though that one is bit further down the road in the future.”

What products can be made from carbon monoxide?

“If we add hydrogen to carbon monoxide, we can produce methanol. That’s a fuel that has been in high demand in recent years. Especially in the maritime sector. We are looking into that as a way to form partnerships. We can work on renewable sources of energy. If there is a surplus of wind or solar energy, our processes can work on those. We basically have the ability to make green chemicals and green fuel. That’s a huge advantage over some of our competitors, among other things.”

What is the impact on the environment?

“We convert the captured CO₂ so it doesn’t end up being released into the air. We’ve got a business model that focuses on reusing that CO₂ locally. We are running a circular project. Storing CO₂ is not something that we actually believe in. That is an interim solution. Right now, it’s the best solution to keep it from disappearing into the atmosphere. It is a good solution for the time being. But not in the long term. Also, it involves huge costs to store all that and have it hauled away by ships.”

Do you think the companies will want to participate?

“There is so much pressure from governments and Europe to do something about it. The CO₂ tax is constantly rising. It is currently 80 euros per tonne. Governments are pushing companies to start producing in a sustainable way. I believe that there is a will. We have a long-term vision. Yet you cannot change industry in just a few years.”

You are a spin-off of the University of Antwerp. How important is it to have a university behind your project?

“We are a spin-off from the Plasmant research group. That gives us credibility, of course. It has taken more than 10 years of research in conjunction with the university. We are based in the Port of Antwerp. But we are already venturing out into the world. Our technology can be rolled out all over the world. Then I’m looking at all ports, from Singapore to Rotterdam.”

Source:

Innovation Origins, press release, 2022-07-07.