Decarbonize and store renewable power in the gas grid: Demonstrated by Electrochaea’s power-to-methane project

Power-to-methane project successfully completed by Electrochaea and Regio Energie Solothurn, demonstrated storing power from the electrical grid in renewable methane

The power-to-methane plant, a joint project between Electrochaea and Regio Energie Solothurn. Here, excess electricity and biogenic CO2 are converted into renewable methane for the Swiss gas grid. (c) RES, 2019.

The power-to-methane project, successfully completed by Electrochaea and Regio Energie Solothurn, demonstrated that Electrochaea’s technology is capable of storing power from the electrical grid in renewable methane. The fully functional, scalable and marketable technology, proven by the Munich-based cleantech company, provides a solution for sustainable energy storage and decarbonization to gas network operators, energy suppliers, climate-conscious communities and CO2-intensive industries.

Power-to-methane allows gas network operators to replace natural gas with CO2-neutral renewable methane, while energy suppliers and municipalities have the option to cost-effectively store electricity from renewable energy sources, in large quantities and over long periods of time, to balance the supply and demand for electricity. Industrial companies can significantly reduce their CO2 footprint by re-using CO2, instead of emitting it.

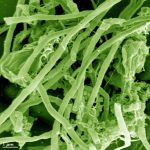

Electrochaea, one of the first power-to-gas technology providers, uses microorganisms called archaea to produce renewable methane from biogenic CO2 and green electricity in its biological methanation process. The resulting renewable methane, made in large quantities, over long periods and at low cost, stores power in a chemical form, methane, that replaces any use of fossil-fuel derived natural gas. Biological methanization is CO2-neutral, as it uses CO2 emitted by various industrial sources.

At the heart of the technology are bioreactors in which the archaea produce methane from CO2 and hydrogen split from water. Electrochaea holds patents on the world’s most efficient Archaea strain, with a productivity twenty times higher than comparable microorganisms.

The reported project results are from the power-to-methane plant connected to the hybrid plant of Regio Energie Solothurn in Switzerland. The plant with Electrochaea technology is a reference plant of the recently completed Store & Go project, which compared three different methanation technologies. In addition to Electrochaea and Regio Energie Solothurn, the project involved the Hochschule für Technik Rapperswil, the Ecole polytechnique fédérale Lausanne, the Swiss Federal Laboratories for Materials Testing and Research and the Swiss Gas and Water Industry Association.

The results at a glance:

- High quality methane gas that meets the stringent requirements for injection into the gas networks in the USA and the EU

- Energy efficiency of 89 percent including waste heat management

- Successful operation of the bioreactors at moderate temperatures (up to 65 degrees Celsius) and pressures between 1-10 bar – this corresponds approximately to the pressures within bicycle tires (racing bike: 5-10 bar)

- High flexibility and responsiveness of bioreactors: start-stop operation, constant gas quality at partial, half and full load (>97 percent methane in the output gas)

- Successful proof that the power-to-methane plant and its bioreactors can be operated remotely

- Successful proof of intelligent coupling with the electricity, gas and heat networks

- Positive evaluation of various commercially viable applications for the methane gas inindustry, private households and as a renewable fuel

Dr. Doris Hafenbradl, CTO of Electrochaea: “We are more than satisfied with the results of the STORE&GO project. We have repeatedly shown that the microorganisms in our reactors function without any problems. In this project, we were once again able to demonstrate that we have also created a bioreactor design that optimally supports and emphasizes the qualities of our biocatalyst. We would like to thank all our project partners for the excellent results and target- oriented cooperation”.

“It’s impressive how the Archaea have been able to convert CO2 and hydrogen into 100% renewable methane using biological methanation.” Says Andrew Lochbrunner, Project Manager STORE&GO

The results are based on more than 1,200 operating hours and injection into the Swiss gas grid of over 13,800 Nm3 of biomethane.

In February 2020, it was announced that the biological methanation plant with Electrochaea’s archaea at the Solothurn hybrid plant was awarded the Watt d’Or energy prize, presented by the Swiss Federal Office of Energy.

About Electrochaea GmbH

Based on biocatalysis, Electrochaea offers a key power-to-gas technology, which has been patented several times nationally and internationally. It recycles CO2 at low cost and at the same time produces eco-methane from surplus electrical energy that can be stored and used as required. The first industrial- scale plants have operated successfully in the USA, Switzerland and Denmark. Plants with a capacity of over one gigawatt are planned by 2025. Electrochaea technology was recently awarded the Swiss energy prize Watt d’Or and listed by FOCUS magazine as one of the most important technologies for climate and environment. 23 employees work for Electrochaea in Denmark and at the headquarters in Munich-Planegg. CEO is Mich Hein.

About STORE&GO

STORE&GO stands for Innovative large-scale energy STORagE technologies AND Power-to-Gas concepts after Optimisation. The international project was launched in 2016 as part of Horizon 2020, the European Union’s research and innovation programme for research and innovation. 27 project partners from six European countries want to further develop the power-to-gas technology. Research is being conducted using three different power-to- gas concepts at three locations in Germany (Falkenhagen, Brandenburg), Italy (Troia, Apulia) and Switzerland (Solothurn). In Switzerland, in addition to Regio Energie Solothurn, Electrochaea, the Rapperswil University of Applied Sciences, the Ecole polytechnique fédérale Lausanne, the Swiss Federal Laboratories for Materials Testing and Research and the Swiss Gas and Water Industry Association are involved in the project.

Source: Electrochaea, press release, 2020-03-19.