Consortium Introduces Molten Salt Regeneration System for CCU

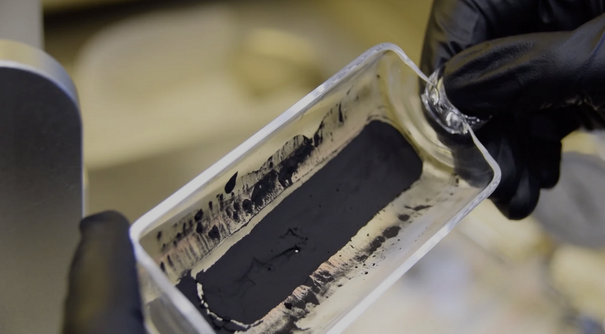

UP Catalyst CO2-derived carbon nanotube electrode material boosts cycle life in Na-ion batteries

UP Catalyst, a leading Estonian nanotechnology company, will, together with a consortium of industry experts develop a revolutionary molten- salt-regeneration technology based on circular-economy principles. The new system has the potential to, significantly reduce waste, and it allows the reuse of carbonate salt up to 100 times. The project, named MoReCCU, has received funding through EIT Manufacturing’s Open Call for Proposals, under the Regional Innovation Scheme (RIS).

As raw materials are crucial to aid the transition from a fossil fuel-based economy to a carbon-neutral circular economy, there is a growing need for sustainable ways to produce and reuse critical raw materials like molten salt. Although carbonate salt used to be a relatively cost-effective material, its widespread use in energy storage applications has led to a 260% price increase in the last 3 years.

The idea for the project called MoReCCU, or Molten Salt Regeneration for Carbon Capture and utilization, was born from the need to maximise resource efficiency. UP Catalyst reprocesses CO2 to produce carbon nanomaterials and graphite, using the electrolysis method with molten salt used as an electrolyte. Renowned experts from the industry and academia joined forces to optimise the technology of Molten Salt Carbon Capture and Electrochemical Transformation (MSCC-ET).

This helps to make carbon nanomaterials and graphite production directly from industrial exhaust CO2 net negative. The initiative received financial support of 560K€ € from EIT Manufacturing, Europe’s leading manufacturing community within the European Institute of Innovation and Technology (EIT), a body of the European Union.

During the project, a semi-automated system that circulates molten salt will be constructed by removing the electrolyte mixture’s impurities. This results in both the preservation of the salt for reuse and an improvement in the quality of the carbon produced.

“It is a game-changing solution that will enable manufacturers to not only regulate the quality of their product but also address resource depletion and lower production costs”, said, Luisa F. Cabeza, Professor at the University of Lleida and consortium partner of the project. Molten salt regeneration is an ideal alternative to salt mining that not only solves environmental issues but also enhances vital production factors such as energy efficiency.

“We are working to implement the best industry practices; thus, we want to produce high-purity carbon through a sustainable process, avoiding long purification cycles in the lab later on”, said, Sander Trofimov, project lead and Production Manager at UP Catalyst.

Dr. Konstantinos Georgoulias, EIT Manufacturing RIS and EU Affairs Director, said: “To accelerate the European green transition, we need to focus on creating new sustainable technologies, as well as optimizing the existing ones. “ We are happy to support the MoReCCU project, which promotes circular manufacturing and adheres to the EIT Manufacturing strategic vision for the future of the industry”.

The kick-off meeting took successfully place in January 2023. As the project leader and technology owner, UP Catalyst will coordinate the technical and operational activities. The University of Lleida will conceptualise the system and determine the key requirements. The Slovak University of Technology in Bratislava will be responsible for the design of the molten salt regeneration system, which will be later constructed by consortium partner INEGI.

Contact

Sander Trofimov

Production Manager at UP Catalyst

Tel.: +372 5300 3967

E-Mail: [email protected]

Source:

UP Catalyst, press release, 2023-02-15.