Sustainability gains through enzymatic recycling – ARC 2025 Interview Series: Innovators at work

With Lars Blank, RWTH Aachen

On 19-20 November 2025, the Advanced Recycling Conference (ARC) in Cologne, Germany, once more unites industry leaders, technology providers, researchers, innovators, and policy-makers to address urgent recycling challenges in various waste-streams. Alongside core-topics like plastics and polymer recycling, this year’s event places strong emphasis on pollution-intensive sectors like textile and automotive, that pose significant environmental problems due to their complex material streams.

To address these challenges, ARC 2025 spotlights four new focus areas: biochemical recycling, textile and automotive recycling, and advanced digital tools such as AI-enabled sorting, traceability systems, and process optimisation for scale up.

These solutions complement established recycling methods across physical processes (extrusion, dissolution), chemical recycling (solvolysis), and thermochemical techniques (pyrolysis, thermal depolymerisation, gasification), as well as carbon capture and utilisation (CCU), that remain key-elements of the ARC program.

A key figure in the field of enzymatic recycling is Professor Lars M. Blank, Head of Applied Microbiology at RWTH Aachen University , renowned for his cutting-edge research harnessing microbial metabolism to convert plastic monomers into valuable biochemicals and bioplastics. His work pioneers enzymatic degradation of polymers like PET, aiming to overcome barriers in plastic recycling through innovative biotechnology.

Register here to maintain on top of the advanced recycling game and be prepared for challenging EU-recycling targets across several legislations: https://advanced-recycling.eu/registration/

In an exclusive interview, Lars highlights the energy efficiency and sustainability gains of enzymatic recycling, its challenges scaling from lab to industry, and how interdisciplinary partnerships accelerate real-world applications. He stresses the need to integrate biological approaches alongside chemical methods to keep carbon in the cycle.

1. Innovation & Sustainability

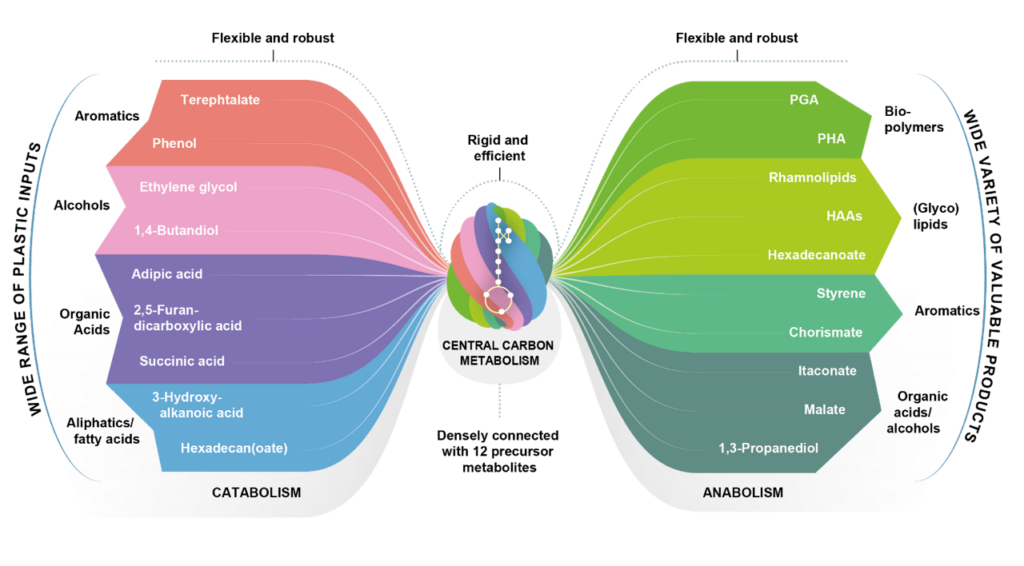

The research of your department of applied microbiology combines metabolic engineering and microbial biotechnology to advance enzymatic recycling. In this process plastic monomers are used as alternative carbon and energy source and thereby replace sugars, contributing to an envisaged land-free biotechnology. Working with experts in pyrolysis, technical chemistry or enzyme catalysis generates such plastic monomer mixtures. For example engineered enzymes act like molecular scissors to break down polymers such as PET into their original building blocks: the monomers ethylene glycol (the E in PET) and terephtalic acid (the T in PET). What are the main challenges and opportunities when using engineered microbes and/or enzymes to turn plastic waste into valuable biochemicals? How does this approach help create a more sustainable circular economy?

Lars Blank: Often, the low energy conditions required for biocatalysis are mentioned, however, depending on the catalytic route process engineers can do heat integration and many more tricks to become energy efficient. For me the application for biotechnology can find its niche where chemistry struggles, e.g., plastic/monomer mixtures into a single product. We can engineer microbes that can utilize such different molecules as alcohols, organic acids, and aromatics into bioplastic or other products of value. The challenges in biotechnology are manifold, and we have to learn not to repeat all again and again. The idea of using polymers, degrading them to monomers, and using these monomer mixtures as food for microbes is not at all new. After four decades or so are second generation carbon sources such as wheat straw and corn stover still not a reality. Why I am hopeful? We can identify plastic fractions which do not contain all the possibilities, like chlorine from PVC or bromides from flame retardants. Surely, these additives are a challenge we have to tackle when moving from PET to more mixed plastics.

How do such approaches contribute to sustainability? André Bardow and his group educate us that about 500 million tons of virgin plastic per year CAN BE produced sustainably, however, only if recycling quota above 75% are reached. Surely, we do not have nice, clean, sorted plastic at the 75% of all plastic used, hence, we need any technology that keeps the carbon in the loop.

2. Sustainability Gains Through Breakthrough Technology

Enzymatic recycling offers a gentler, more precise alternative to chemical recycling options by using biological catalysts to selectively break plastics down at the molecular level. Studies[1] have shown that enzymatic PET recycling can reduce greenhouse gas emissions by up to 43% and total supply-chain energy use by as much as 83%, compared to making new plastic from fossil resources. What do you see as the main challenges and opportunities in applying microbial and enzymatic technology to plastic waste valorisation, especially in delivering measurable sustainability gains in a circular economy? What key breakthroughs have you as a professor observed in recent research to improve the efficiency and reduce environmental impact of such processes?

Lars Blank: While the enzymatic degradation of PET, and to some extent PLA made incredible strides, from some observable activity in specialised laboratories to few hours at industrially relevant scales, the challenges are in the detail. How about the purification of both PET monomers? Yes, terephthalic acid can be cheaply recovered, however ethylene glycol not so cheap. And, are additivized PET like opaque PET also possible? A different challenge is the production of an acid. Is the enzyme low pH stable or is pH control required? If the latter, how is the atom efficiency of the process, as a base has to be added? Again, we, as microbiologists can work with all technologies that can break down the polymer to its monomers. Hence, the best suited technology can be chosen, taking environmental impact directly into account.

3. Challenges & Opportunities

Scaling up enzymatic recycling brings both efficiency and economic challenges, such as enzyme production cost, the need for precise process control (temperature, pH, reaction time), and difficulties with mixed or contaminated waste streams. Industrial analysis estimate that process innovations can lower costs by as much as 74% compared to earlier approaches[2]. What specific obstacles do research and industry face in bringing enzymatic recycling from laboratory to pilot scale, and what market or policy changes would help accelerate industry adoption?

Lars Blank: The PET market is gigantic, hence, to make any impact one requires a large plant of at least 50,000 tons of plastic and ideally larger. This comes with invest risks, with all the market uncertainties including changes in policies and such simple aspects as tax. More generally, in biotechnology, we would profit if we would get on the same playing field. Carbon pricing, as implemented in the EU is such a measure to guide us in such a future. Is it happening? The CO2 price is still to low to become on pair with the traditional routes.

4. Collaboration & Industry Dynamics

Successful enzymatic recycling technologies require input from biotechnology, the chemical industry, and the waste management sector. In consequence, partnerships have proven critical in optimising feedstock sourcing, logistics and process control. How do you approach building these collaborations, e.g. in research- or industrial consortia? What kinds of industry partnerships or cross-sector exchanges appear most valuable for scaling and validating enzymatic recycling in settings of the industrial world?

Lars Blank: In the EU projects we coordinated we had industrial partners that had (and still have) the plastic recycling challenges in house. Here, even “clean” plastic fractions of defined origin can only be incinerated. Working directly with the challenge owners is very fruitful. I am not starting with the German waste system as I understand it, as here everything will work with the companies handling the waste, as long as someone pays for it. With a step towards such a novel value chain, our colleagues Regina Palkovits and Jürgen Klankermayer started the WSS funded research canter catalaix. In catalaix 17 groups from RWTH Aachen University and FZ Jülich cover all disciplines from plastic sorting, to catalysis, and system analysis. You will see many collaboration between disciplines.

5. Future Innovations

Enzymatic recycling works especially well for plastics such as PET (e.g. from bottles, textiles) but faces major hurdles with other plastics or mixed waste streams, due to the need for different enzymes or pre-treatments. Which plastic wastes or composite streams do you consider best/less suited for enzymatic recycling today? How transferable is the process to other waste categories, and what further improvements or research would make enzyme-based recycling viable for a broader range of materials? Painting an ideal scenario, what does the future of biochemical recycling bring?

Lars Blank: As mentioned, enzymatic depolymerisation is just one possible route to come from polymers to the monomers. The high selectivity, and in the case of PET, the high rate of plastic degradation is clearly arguing in favour. We see much progress on other polyesters, while first encouraging reports exist on other heteroatomic bonds, like polyamides (PA), polycarbonates (PC), and polyurethanes (PU). While the technologies are slow and often only work on oligomers, the progress will be rapid, I am sure. We will see which technology will prevail. What I have to date a strong opinion about, which would need truly interesting new developments, is the enzymatic degradation of olefins, carbon-carbon bond containing plastics such as PE and PP. While the literature reports a lot, I am still convinced that most reports are artifacts or utilize non-relevant PE derivatives (e.g., low molecular weight, containing oxygen). To further extent to other materials? Some plant material like the mentioned wheat straw would be great, but the technology is complex and hence not commercially competitive until the current market conditions.

How about having biodegradable material for material we put by purpose into the environment? We should not leave any plastic in the environment, but if we lose, it will at least disappear. An example are seed coatings, where plastic is required to date. These small amounts of plastic have to be biodegradable in the future. How about taking the end-of-life of the material into its original design? We argue for recycling-privileged polymers that come with bonds that can in a recycling environment easily be broken. The vision is clear, non-fossil feedstocks (i.e., biomass, CO2, plastic waste) are converted to polymers that allow high recycling quota, and come with bonds that allow emergency biodegradation.

[1] https://www.nrel.gov/news/detail/press/2021/analysis-shows-enzyme-based-plastics-recycling-is-more-energy-efficient-better-for-environment

[2] https://www.nrel.gov/news/detail/program/2025/plastics-recycling-with-enzymes-takes-a-leap-forward

Source: Advanced Recycling Conference, original text, 2025-10-01.