Renewable Carbon is Key to a Sustainable and Future-Oriented Chemical Industry

The equivalent to decarbonisation in the energy sector is a transition to carbon from renewable sources in the chemical and plastics industries. The nova-Institute published a position paper on the future of chemistry

The chemical industry may only develop into a sustainable sector once it bids farewell to fossil raw materials such as crude oil, natural gas and coal for good and uses nothing but renewable carbon as a raw material in organic chemistry.

Deutsche Fassung: http://news.bio-based.eu/erneuerbarer-kohlenstoff-ist-der-schluessel-zur-zukunft-einer-nachhaltigen-chemie/

However, it is not a decarbonisation, like it is quite reasonably called for in the energy sector, that will help this industry. After all, organic chemistry cannot be decarbonised, as it is entirely based on the use of carbon. This also includes the plastics industry – the modern world is inconceivable without its versatile polymers unless you are prepared to accept considerable sacrifices or higher greenhouse gas emissions.

There are only three sources of renewable carbon: renewable carbon from recycling of already existing plastics (mechanical and chemical recycling), renewable carbon gained from all types of biomass and renewable carbon from direct CO2 utilisation of fossil point sources (while they still exist) as well as from permanently biogenous point sources and direct air capture.

All three sources are essential for a complete transition to renewable carbon, and all of them, in equal shares, should be used by the industry, supported by politics and accepted by the population.

In a sustainable chemical industry, bulk chemicals will primarily rely on chemical CO2 utilisation through methane, methanol and naphtha, while specialty chemicals and complex molecules will more likely be produced from biomass (and CO2 fermentation). At the same time, mechanical and chemical recycling will reduce the need for additional renewable carbon on the whole.

Whereas traditional recycling re-uses products and materials, the use of biomass and direct CO2 utilisation is tantamount to a recycling process which also constitutes part of an extended circular economy.

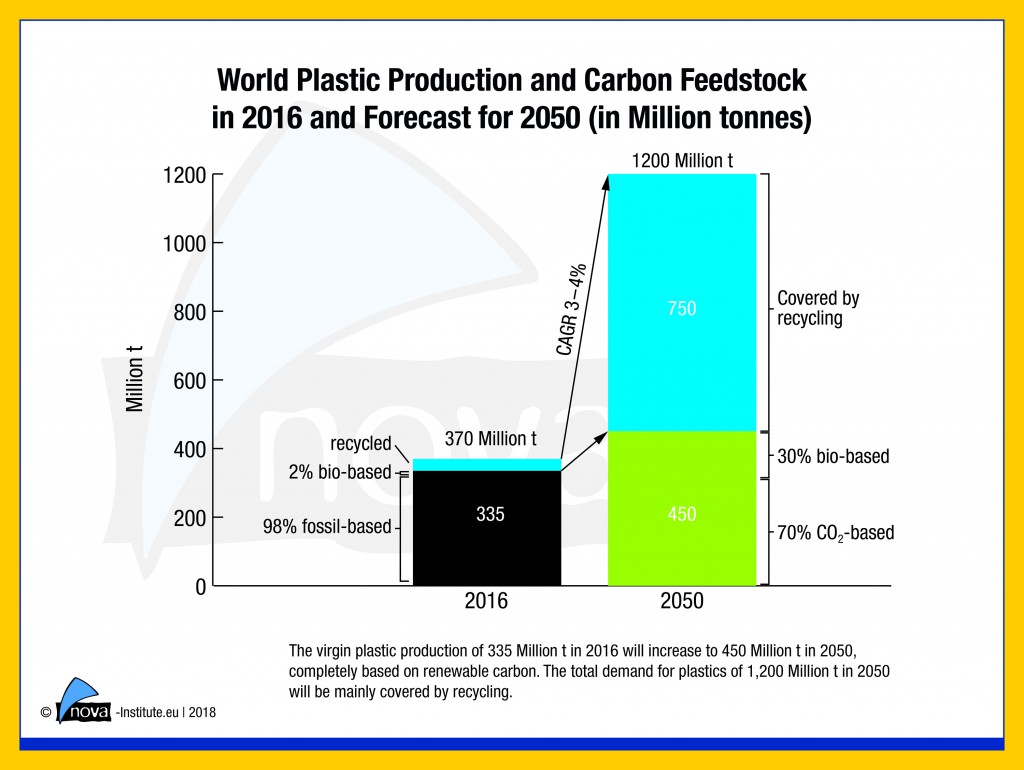

The authors show how the complete conversion of the chemical industry to renewable carbon can look like and which cultivation areas are necessary for the biomass and renewable energy demands. A future scenario for the plastics industry might look as follows (see figure): Due to its annual growth of three to four per cent, the global production of plastics will soon reach the mark of 400 million metric tons per year.

Pronounced recycling efforts might hold the continuously growing demand for new plastics between 400 and 500 million metric tons by 2050. This need could then be covered by, for example, 30 per cent biomass and 70 per cent direct CO2 utilisation. The total of biomass required to do so would amount to roughly 1% of biomass currently used around the globe in all fields of application (13–14 billion metric tons, of which 60 per cent alone are attributable to animal feed for the production of milk and meat).

Finally, the authors discuss thirteen concrete measures that are politically suited to initiate and accelerate the change towards renewable carbon. These include for example taxes on fossil carbon, renewable carbon quotas for bulk polymers or annual reporting by the chemical companies on their share of renewable carbon in production.

24 chemistry and plastic experts from industry and research already support this position paper, further supporters are welcome.

The full position paper, called “nova paper #10 Renewable Carbon is Key to a Sustainable and Future-Oriented Chemical Industry” (2018-08) can be downloaded in English and German at www.bio-based.eu/nova-papers

Press release as PDF file: 18-08-06 PR nova-Paper 10 renewable carbon

Source: nova-Institut GmbH, press release, 2018-08-06.