Prometheus’ New e-Kerosene Tech Drives SAF Cost Below $2.50-per-Gallon, Makes Fischer-Tropsch Obsolet

Prometheus announce their new e-kerosene pathway – the first technology since Fischer-Tropsch a century ago to convert electricity and CO2 into carbon neutral jet fuel in a single proces

SAF is too expensive. Most buyers aren’t willing to pay a green premium and until now there hasn’t been a technology capable of making carbon neutral jet fuel at the right price. What is the right price for SAF (sustainable aviation fuel)? There’s only one – it’s the price that can compete with jet fuel made from oil. For the past 15 years, e-fuel producers have promised lower fuel prices but have failed to deliver. It’s not the cost of electricity that’s holding e-SAF back. Over the last decade, the cost of solar has dropped as low as $0.01 per kWh on multiple utility-scale solar projects. The problem is the technology everyone has adopted to make e-fuel – Fischer-Tropsch. Fischer-Tropsch will always be too expensive to make cost-competitive e-fuels no matter what the price of electricity is. The demand for SAF is there. The airlines want it. Their customers want it. What’s been missing is a technology that can make carbon neutral jet fuel at a price that beats the price of fossil jet fuel.

At Prometheus, we’ve created this technology. Today, I’m proud to announce our new e-kerosene pathway – the first technology since Fischer-Tropsch a century ago that can convert electricity and CO2 into carbon neutral jet fuel in a single process. Most importantly, the SAF that our e-kerosene pathway produces can compete on price with jet fuel made from oil, making Fischer-Tropsch obsolete.

Prometheus’ e-kerosene pathway marks a revolutionary advance in e-fuel production. Our pathway is the first ever created to use integrated low-cost direct air capture (DAC) of atmospheric CO2. It’s the first pathway that does not use hydrogen to make fuel – considered a “holy grail” in the field of electrochemistry. And the entire system was designed to run without a connection to the grid, powered solely by remote intermittent renewable electricity – the cheapest electrons on Earth. The jet fuel it produces does not need refining and is 100% carbon neutral, making it a true SAF. Significantly, the cost to make our jet fuel is the same or less than the cost of fossil jet fuel at any scale of production, whether it’s one gallon or one million gallons.

I realize these are extraordinary claims, and so today, I’m also proud to share for the first time details about our technology that make this new kerosene pathway possible. At Prometheus, we’ve spent the past six years building our IP moat across multiple patent families and can now reveal more information about the innovations we’ve pioneered. Our e-kerosene pathway employs a new technology we call Electrochemical Oligomerization, introduced by and proprietary to Prometheus.

Electrochemical Oligomerization

This new technology gives us the ability to make large hydrocarbon molecules using a process that is 100% percent electrochemical. We call this ability carbon-carbon chain growth Electrochemical Oligomerization. Standard oligomerization refers to the coupling of small molecular units into mid-size molecules by sequential addition. A similar carbon chain growth mechanism occurs in Fischer-Tropsch as part of a thermochemical process in reactors with high pressures and temperatures.

In our Hydrocarbon Electrolyzers, we achieve carbon-carbon chain growth oligomerization similar to that of Fischer-Tropsch, but using a 100% electrochemical process that occurs in water at room temperature and atmospheric pressure. Where Fischer-Tropsch uses high temperatures and pressures to make long-chain hydrocarbons, we use electromagnetic fields and electric currents. Our method is much cheaper.

The kerosene rises to the surface of our electrolyte (salty water) as a layer above the water due to its lower density and hydrophobicity (i.e., “oil and water don’t mix”). The separation occurs in a simple oil / water separator in which the kerosene pours over a weir, while the electrolyte is returned to the stack for continued production of fuel. The final product is synthetic paraffinic kerosene (SPK), a clean fuel that doesn’t have the harmful “aromatic” chemicals that oil-based fuels do.

© Prometheus

What Is It Exactly that Makes Prometheus’ 100% Electrochemical e-Kerosene Pathway Cheaper than Fischer-Tropsch?

The Fischer-Tropsch (FT) process is expensive for several reasons:

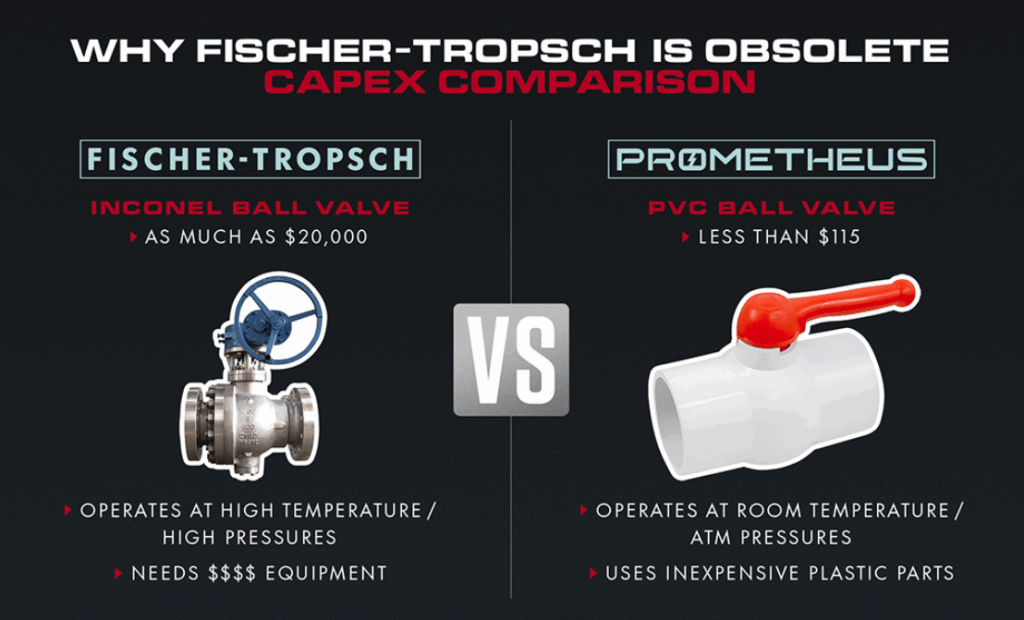

- FT operates at high temperatures and pressures, requiring expensive materials and components – high CAPEX (example: a single Inconel ball valve can cost as much as $20,000)

- The high temperatures and pressures and high CAPEX of FT require 24/7 operation, which requires a grid connection

- FT’s CO2 comes from point source smokestacks, which requires an industrial site. If conventional DAC is used this is even more expensive than point source

- The combination of needing grid electricity and an industrial site means that electricity for FT is expensive, and proving that its fuel is carbon neutral requires additional costs such as the purchase of certificates or reducing the value of the fuel by increasing its carbon intensity

- The product of the FT process is a mixture of gases, liquids, and waxes, that need to be further refined and not all of which become the desired SAF product

- The projects planned with FT are large scale requiring significant upfront capital for first of a kind (FOAK) projects putting billions of dollars at risk. This is because of the significant exponential scaling factors of projects of this type

Prometheus’ electrochemical e-kerosene process is low-cost for several reasons:

- It operates at atmospheric pressure and low temperature, meaning its fuel-production system can be built using inexpensive plastic components – low CAPEX (example: a PVC ball valve can cost less than $115)

- The low temperature, pressure, and CAPEX allow the process to run intermittently, making cheap, remote, off-grid solar its ideal power source

- Its CO2 comes from DAC, allowing it to be sited in remote locations with low land costs and no need for grid connections

- The combination of intermittent operation, low-cost Prometheus No-Desorb DAC, and no grid, with the ability to site fuel production anywhere, means the electricity inputs for Prometheus’ fuels can be the cheapest electrons in the world today – around 1 cent per kWh. By using the lowest cost solar panels, low-cost east-west ground mount racks, low voltage DC, no or few batteries, and avoiding the costs related to grid connections, an electricity price of less than 1 cent per kWh is well within reach

- The product of Prometheus’ process is finished kerosene. All that’s needed to turn this kerosene into SAF is a small amount of required additives such as lubricants, anti-statics and the like commonly required to meet ASTM specs for SAF from SPK. Because the ASTM for SAF is pathway dependent, and our pathway is new, a new certification will be required

- Prometheus kerosene is low cost at any scale, from one gallon per day to millions, so a first of a kind (FOAK) project can be any size. Any size project is simply a multiple of the same stack, with the cost scaling linearly with production volumes

How We Get to $2.50 for a Gallon of Prometheus SAF

When we say we can make SAF at the right price, we mean less than $2.50 per gallon, here’s how that breaks down:

- Because the cost of our materials is so low, we estimate our capital component cost to be less than $1 / gallon, even when running intermittently on off-grid solar

- With our record low CO2 capture cost, our cost of carbon is less than $0.50 / gallon

- Assuming an electricity cost of $0.01 per kWh, our electricity input cost is approx. $1 / gallon

That brings the total cost of a gallon of Prometheus SAF to less than $2.50 / gallon – in other words, a price that can compete with fossil jet fuel in commodity markets.

Prometheus can make the SAF that airlines and travelers have been waiting for – a fuel that’s 100% carbon neutral, but doesn’t require people to pay more. With our technological breakthrough, there’s no longer any reason to build Fischer-Tropsch systems with costs that are 5 X higher than commodity market prices. This is why Fischer-Tropsch is now obsolete.

Over the past year, we’ve scaled our new e-kerosene pathway from benchtop to kerosene production in full-sized commercial-scale cells. We’re now moving into pilot-scale production. Stay tuned for details early in the new year about the next fuel we’ll be making with the Prometheus e-kerosene pathway – low-cost e-diesel.

Source: Prometheus Fuels, press release, 2025-12-24.