How to build a more climate-friendly chemical industry

The successful transformation of the chemical industry requires many building blocks and many hands because chemistry is the foundation for many value chains

Reducing emissions in this sector will be tough – but the rewards would be significant. Image: REUTERS/Annegret Hilse

- Cutting chemical industry emissions could have a huge impact globally.

- A multi-pronged approach will be necessary to achieve this.

- The benefits could spread far beyond the chemical sector.

The chemical industry has a vital role to play in the climate discussion. On the one hand, chemical products are essential to many low-carbon technologies – including renewable energy, housing and mobility. Moreover, chemistry will be needed to develop resistant materials adapted to more severe weather conditions. On the other hand, chemical production is energy and CO2-intensive. This is why this sector is classified as “hard to abate.”

Transforming chemical production can have a substantial global impact

Currently the key basic steps of chemical production produce substantial greenhouse gas (GHG) emissions. However, “hard to abate” does not mean “impossible to abate”. Yes, it will be challenging, but in light of the enormous potential CO2 savings in the chemical industry, this is a challenge we must accept.

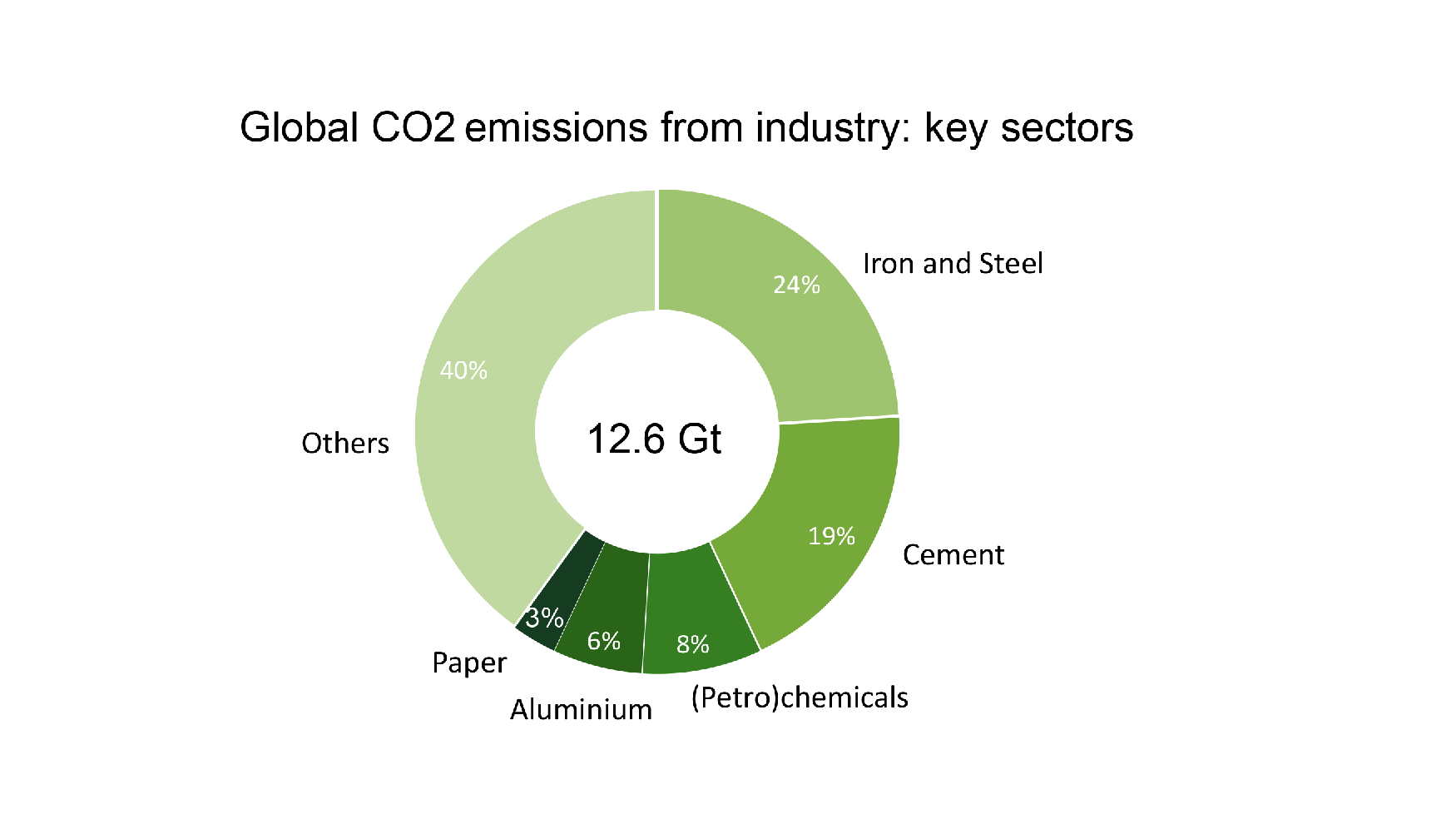

Emissions from industry exceed the emissions from either the buildings or transport sector, and represent more than 30% of global GHG emissions. Within the industrial sector, chemical production together with cement production and metals are the biggest sources of emissions. As such, advances in chemical production can have a profound effect globally.

A breakdown of industrial sector emissions, 2014 Image: Schneidewind, Die Große Transformation, 2018

Our products are made up of 50% carbon, so a carbon-free chemical industry is simply not possible. Although the chemical industry cannot avoid carbon, it can use carbon more efficiently and reduce its GHG emissions.

A multi-pronged approach is needed – with R&D playing a crucial role

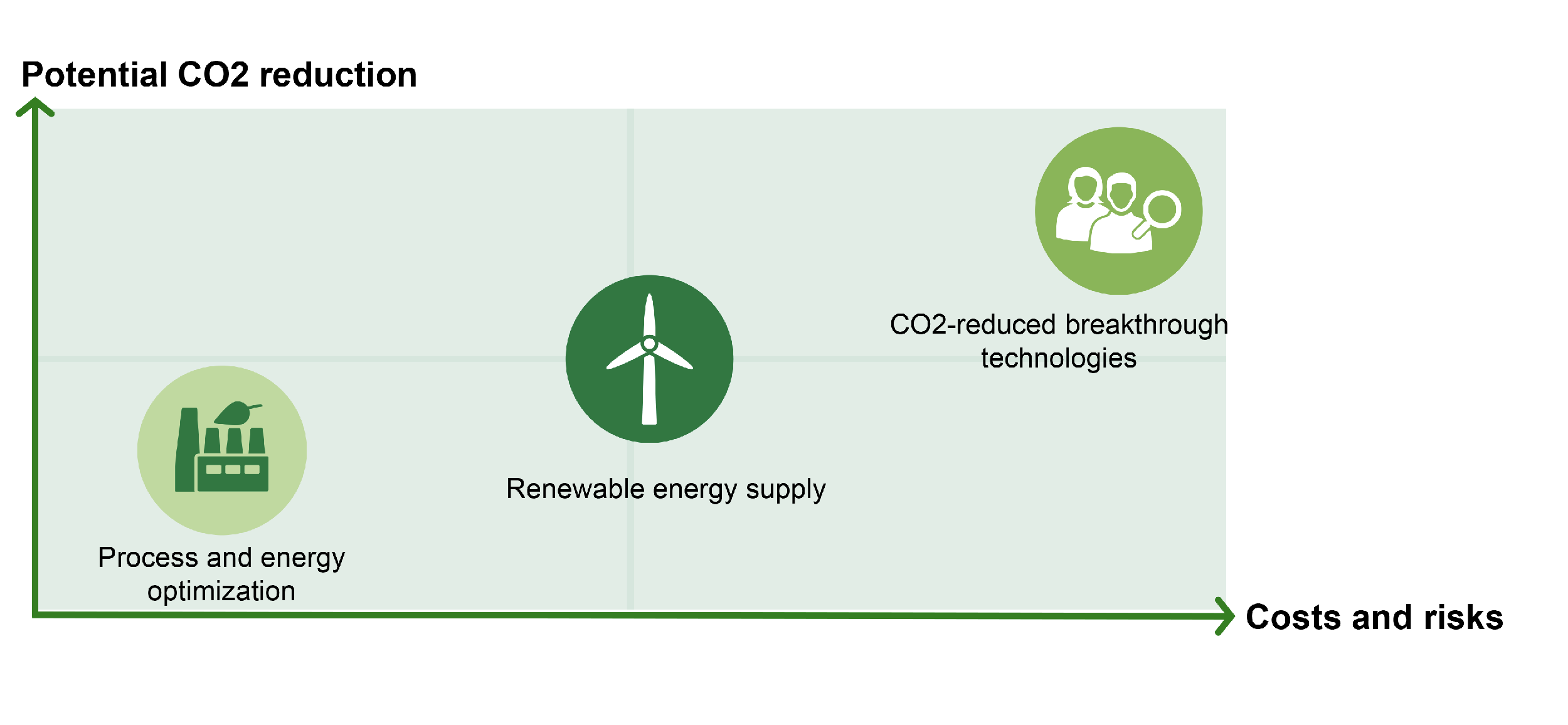

BASF has identified three main areas for addressing GHG emissions in the chemical industry (see figure below):

Three areas of focus for the chemical industry. Image: BASF

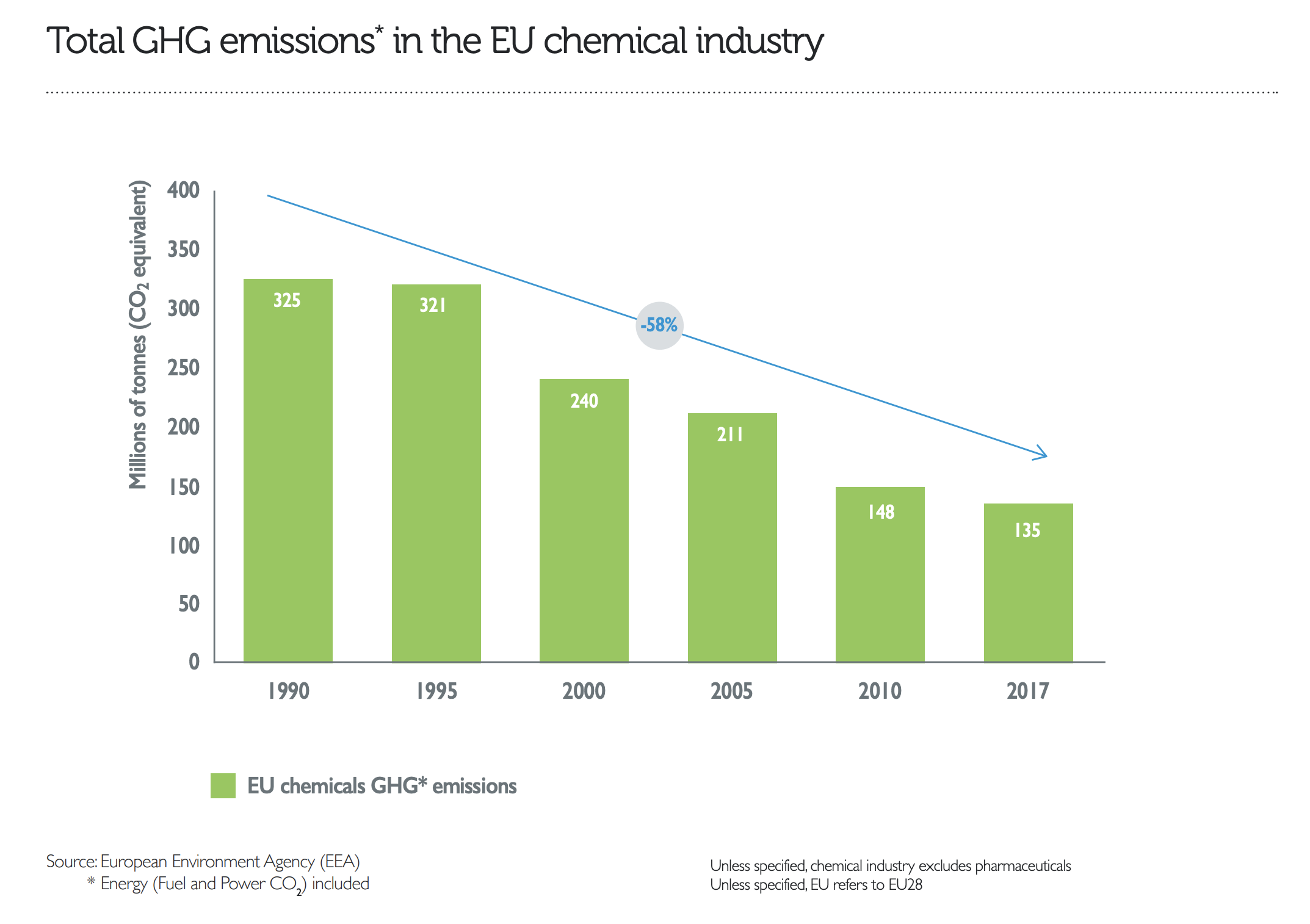

Since most companies have already implemented major efficiency improvements and substantially reduced GHG emissions, further efficiency gains will have a relatively modest impact on GHG emissions.

The sector’s emissions have fallen by 60% in the past 30 years. Image: European Chemical Industry Council

The sector’s emissions have fallen by 60% in the past 30 years

Therefore we need to pursue a multi-pronged approach. While continuing to focus on efficiency, we must also pursue breakthrough technologies and utilize renewable energy. Similarly, an array of technologies will be needed to achieve a climate-neutral future. Some technologies will help us avoid CO2 emissions wherever possible, but CO2 capture and new feedstock based on renewable or recycled materials will play an important role as well.

In theory, CO2-free chemical production is possible with existing technologies. But implementing this in the European chemical industry would require more power from renewable sources than will be available in Europe under even the most optimistic renewables scenario. Nevertheless, this is no reason to give up. Instead, it should inspire us to come up with revolutionary new ideas.

We cannot defy the laws of thermodynamics; chemistry needs energy. But we can take innovative and clever approaches. One example is methane pyrolysis, which splits methane into solid carbon and hydrogen using comparatively little energy. If the energy input comes from renewable sources, the process can deliver hydrogen without CO2 emissions.

Time is of the essence. We cannot afford to wait and see what one technology will offer. This is why at BASF we are developing several projects in parallel. Only at a later date will we be able to judge which one is the most successful in which case. For example, one of our projects in our Carbon Management R&D programme is the electrification of exothermic processes such as the steam cracker. This would reduce CO2 emissions from steam cracking by up to 90%. Simultaneously, in cooperation with Linde, we have found a groundbreaking way to produce emission-free synthesis gas.

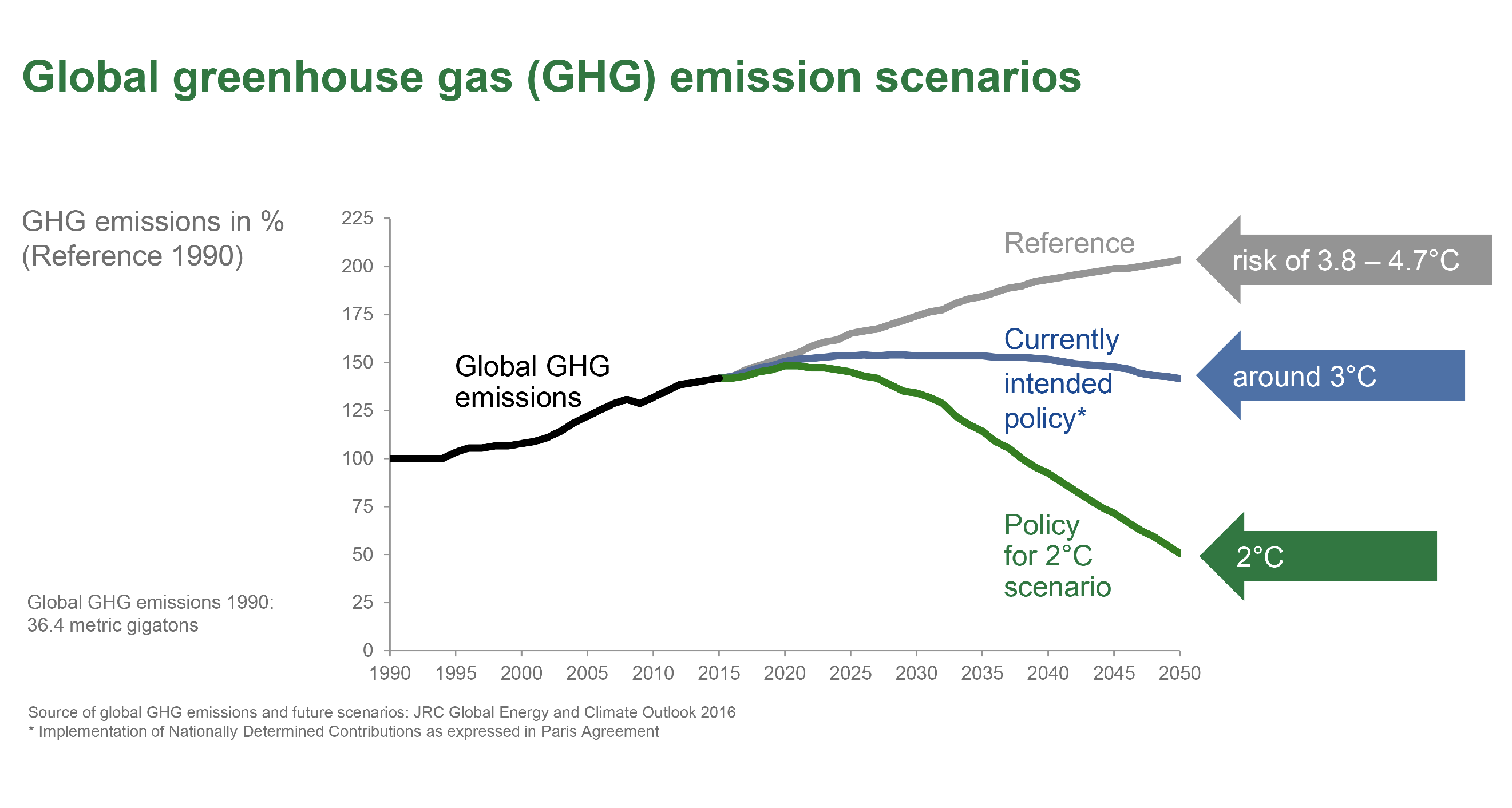

Three possible emission pathways. Image: BASF

A collaborative effort is needed within the sector…

Individual companies cannot transform the chemical industry on their own. Chief technology officers (CTO) are well aware of this. This is why CTOs and experts from more than a dozen chemical companies gathered in summer 2019 to forge new paths. All of us share the goal of dramatically reducing our industry’s carbon footprint. We are eager to explore new approaches or even legal bodies and structures that can accelerate this development.

This is a new approach. Traditionally, companies have emphasised proprietary technologies to gain a key competitive advantage that allows them to succeed in business. But now, going beyond bilateral projects and joint ventures, more and more companies want to join forces to transform the whole sector.

Why is this approach necessary when it comes to new climate-friendly technologies? To show impact, new technologies need to achieve scale. In the chemical industry, upscaling entails massive material and labour costs – which, by the way, is one reason for the lack of start-ups in our sector. Succeeding in the upscaling phase is the tipping point for the transformation of the sector.

Collaboration within the industry will increase the chances of this happening. For successful implementation, however, we need to collaborate across sectors as well.

…and beyond

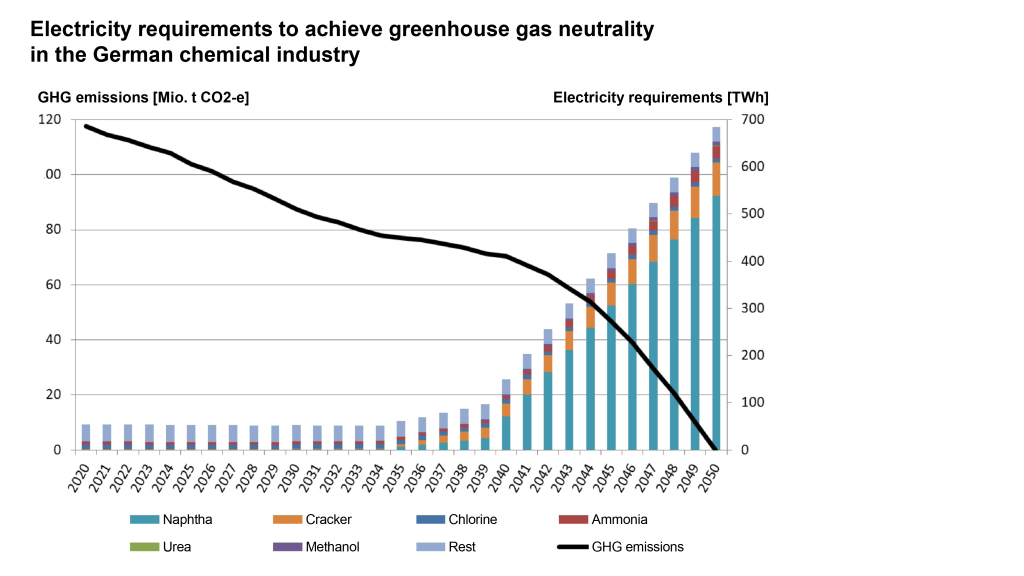

When electrification and new processes come together in the chemical industry of the future, this will increase the demand for renewable power. The power sector must therefore undergo a rapid transformation to prepare the ground for the technologies being developed. For our largest production site in Ludwigshafen, we estimate a threefold increase in power demand – from approximately 7 terawatt hours (TWh) today to more than 20 TWh in the future – which needs to come from renewable sources. But how will renewable energy be reliably provided when and where it is required? There is an urgent need to realistically plan and realize a renewable power supply as well as to figure out how to integrate and transport this energy.

How much power will it take to transition the chemical sector?

Along with the availability of renewable energy comes the question of price. It will be the decisive factor determining whether new chemical processes can compete with CO2-rich processes. The potential of low-emission technologies can be realized only if the necessary infrastructure exists and pioneering work is incentivized, for example, via pricing of renewable energy as long as there is no sufficient global carbon-pricing mechanism. We in the chemical industry will accelerate our efforts to make these technologies available. Let’s also speed up efforts to make them economically viable.

The successful transformation of the chemical industry requires many building blocks and many hands – a team effort. In turn, the benefits will spread far beyond this sector, because chemistry is the starting point and the foundation for many value chains. A viable chemical sector delivers the products needed to realize reductions in other sectors and strengthens the industrial power of economies.

It may be hard to transform, and it won’t happen overnight – but it’s possible if we all want to.

Source: World Economic Forum, press release, 2020-01-21.