Greener Cement and CCUS – IDTechEx Explores Decarbonizing Cement

Green cement technologies including supplementary cementitious materials and emerging production processes you may find in IDTechEx's forecasting

Concrete is a large contributor to CO2 emissions, with its key ingredient, cement, being responsible for 7% of Earth's annual carbon footprint. IDTechEx's report, "Decarbonization of Cement 2025-2035: Technologies, Market Forecasts, and Players", benchmarks green cement technologies including supplementary cementitious materials, alternative fuels, and emerging production processes. According to IDTechEx forecasting, increased deployment of cement decarbonization solutions will avoid a further 422 megatonnes of CO2 emissions each year by 2035.

Concrete is the second most consumed resource in the world, following behind only water. It is a well-understood material with excellent properties, including its strength, robustness, and fire and water resistance. Because concrete will continue to be necessary for building new infrastructure as populations grow and urbanize, simply cutting down on construction isn't an option.

Difficulties of decarbonization

Beyond the massive global demand for concrete, there are other barriers that make cement decarbonization particularly difficult. Cement production is highly localized, and this variation in availability of resources from region to region influences which green cement solutions are possible. The amount of voluntary demand (where corporations voluntarily pay a green premium for low-carbon concrete) and government support is also different in each country. In some areas, governments have already started to stimulate green demand via public procurement for infrastructure projects.

Even when there is a strong driving force for cement decarbonization, it is very challenging to lower the carbon footprint of the underlying cement-making process. The high temperatures required are most straightforwardly provided by fossil fuel combustion. Additionally, cement is made from limestone (CaCO3), which means CO2 is intrinsically released when producing the CaO needed for concrete. Consequently, two-thirds of cement's CO2 emissions remain even when fossil fuels are replaced.

Approaches to producing greener cement

Burning fossil fuels is responsible for 32% of cement's overall carbon footprint. Therefore, switching to alternatives such as biofuels or even hydrogen is one approach to decarbonizing cement. Renewable-powered electrified kilns and heat from concentrated solar power are also being explored, but are at an earlier development stage and have not yet achieved large-scale commercial deployment.

Replacing a fraction of cement with lower-carbon alternatives, known as supplementary cementitious materials, also reduces the amount of CO2 produced per tonne of concrete. Coal fly ash, blast-furnace slag, and calcined clays are already widely deployed in cement mixes, but the availability of these materials varies by region. Only limited amounts of cement can be replaced by supplementary cementitious materials before the performance of concrete starts to suffer. While new materials are being developed to replace up to 100% of cement, they may see slow uptake from the risk-averse construction sector.

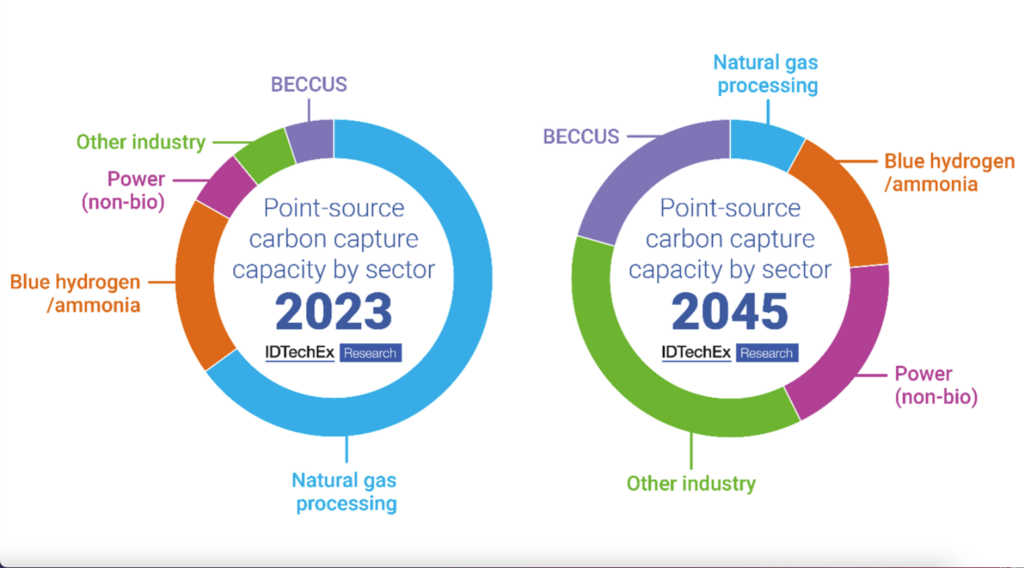

Carbon capture, utilization, and storage (CCUS) is another approach to reducing carbon emissions from cement production. By 2050, several cement sector industry roadmaps predict that this will become the most important green cement technology since it can be retrofitted into existing cement plants and capture ~90% of CO2 emissions. The high cost of this technology means large-scale projects have only started coming online as of 2024/2025, with increased financial support becoming available. For example, the EU Innovation Fund is expected to support several cement sector CCUS projects in Europe over the coming decade. IDTechEx's report, "Carbon Capture, Utilization, and Storage (CCUS) Markets 2025-2045: Technologies, Market Forecasts, and Players", explores different carbon capture technologies and business models.

CCUS, supplementary cementitious materials, petroleum waste-derived fuel, and biomass-derived fuel are expected by IDTechEx to be the most impactful decarbonization approaches within the next ten years. IDTechEx includes benchmarking of various technologies, with readiness levels and costs taken into account.

To find out more about the IDTechEx "Decarbonization of Cement 2025-2035: Technologies, Market Forecasts, and Players" report, including downloadable sample pages, please visit www.IDTechEx.com/Cement.

For the full portfolio of sustainability market research available from IDTechEx, please see www.IDTechEx.com/Research/Sustainability.

About IDTechEx

IDTechEx provides trusted independent research on emerging technologies and their markets. Since 1999, we have been helping our clients to understand new technologies, their supply chains, market requirements, opportunities and forecasts. For more information, contact [email protected] or visit www.IDTechEx.com.

Source: IDTechEx, press release, 2025-04-22.